Undersea Fiber Optic Cables

Everything Everywhere Daily

Deep Dive

- Undersea fiber optic cables form a global network.

- These cables transmit almost all international communication.

- Without these cables, the modern world would be significantly different.

Shownotes Transcript

For many of you listening to the sound of my voice right now, the audio originated from a digital file that was transported across the globe at the speed of light on fiber optic cables. The fiber optic cables, which crisscross the oceans, create a network that unites the entire globe. Almost all the telephone calls, text messages, web pages, streaming videos, and podcasts that travel around the world do so through undersea fiber optic cables.

Without these cables, our modern world would be very different and many of you wouldn't be listening to me right now. Learn more about undersea fiber optic cables and how they work on this episode of Everything Everywhere Daily.

This episode is sponsored by Quince. It's summertime, and that means it's time to bring out the summer clothes. If you're looking to update your wardrobe this summer, I suggest you check out Quince. Quince has all the things you actually want to wear this summer, like organic cotton silk polos, European linen beach shorts, and comfortable pants that work for everything from hanging out in the backyard to nice dinners. And the best part? Everything with Quince is half the cost of similar brands.

By working directly with top artisans and cutting out the middleman, Quince gives you luxury pieces without the markups. I recently needed a new duvet, and I went to Quince and picked up a great one that looked much better than what I had before, and all at a fraction of the price I'd pay elsewhere.

Stick to the staples that last with elevated essentials from Quince. Go to quince.com slash daily for free shipping on your order and 365-day returns. That's q-u-i-n-c-e dot com slash daily to get free shipping and 365-day returns. quince.com slash daily. Hey, Kristen, how's it trackin'? With Carvana Value Tracker. What else? Oh, it's trackin'.

In fact, value surge alert trucks up 2.5%, vans down 1.7%. Just as predicted. Mm-hmm. So we gonna... I don't know. Could sell, could hold. The power to always know our car's worth. Accelerating, isn't it? Tracking. Always know your car's worth with Carvana Value Tracker. Undersea fiber optic cables have been a bit of an obsession of mine ever since I started traveling.

When I started traveling full-time in 2007, my first stops were on islands in the Pacific Ocean. I often had to visit internet cafes, where I found the bandwidth to be somewhere between bad and horrible. For example, when I was in Majuro, the capital of the Marshall Islands, they only had satellite internet at the time. It was about dial-up speeds, and it was incredibly expensive. Having to deal with the internet in the middle of the ocean at this point in time made me curious as to how exactly these islands were connected to the rest of the world.

I visited the island of St. Helena in 2014, which is in the middle of the Atlantic Ocean. Most of the world had pretty good internet by this point, but St. Helena still only had a slow, expensive satellite connection. Over the years, I would periodically check to see if these countries had been connected to the rest of the world via fiber optic cables. And slowly but surely, most, but not all of these islands did become connected to the rest of the world.

For many of these places, being connected to the global communication network was transformative, for better or worse. Over the years, I'd read up on what was happening as billions of dollars were spent expanding this global network, connecting more countries, as well as providing faster and more redundant connections. I had a video call just the other day with someone living in Muldura, Victoria, Australia.

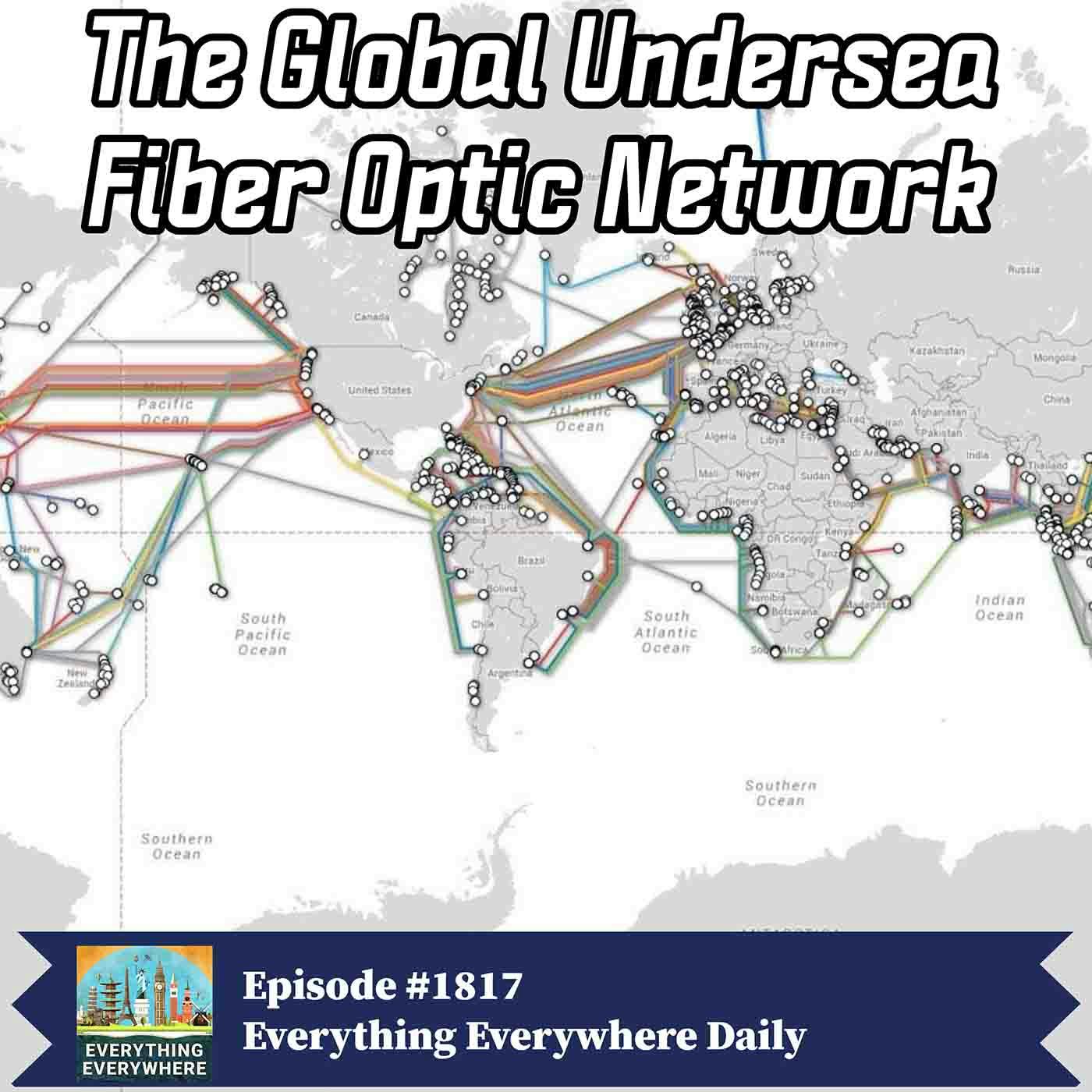

It was the cleanest, clearest video call I've ever had with someone that far away. And it was largely due to the improved connections between Australia and the United States. The network of undersea fiber optic cables is sort of the invisible web that connects the entire world. In a previous episode, I covered the story of the 1858 transatlantic cable, the first such cable which sent telegraph messages between Newfoundland and Ireland. By 1903, cables had been laid across the Pacific Ocean.

Over the years, more cables were laid, expanding the global telephone system. And while it did allow for more communication, international, especially intercontinental telephone calls were extremely expensive. Up until the second half of the 20th century, all cables on the ocean were sending electrical signals. The amount of bandwidth and information that could be sent was still extremely limited. There were two technical advancements which allowed for the use of light for communications instead of electricity.

the laser, which I covered in a previous episode, and the creation of glass fibers which could channel light over long distances. This breakthrough came in 1966, when British scientists Charles Cow and George Hockham proposed that if impurities could be reduced in glass fibers, they could transmit signals over long distances. Cow, who would later win the Nobel Prize, was instrumental in proving that fiber optic communication was feasible.

This was finally put into practice with the first transatlantic fiber optic cable, TAT-8, which was laid in 1988 between the United States, United Kingdom, and France. It had a bandwidth of about 280 megabits per second, or the equivalent of 40,000 telephone circuits. It had vastly more capacity than any other undersea cable that came before it. Today, the performance of undersea fiber optic cables has improved by orders of magnitude over the first one.

The average fiber optic cable today can have a bandwidth of somewhere between 50 to 200 terabytes per second, and future cables might be as high as 250 terabytes per second. There are currently 1.4 to 1.5 million kilometers of active submarine fiber cables on the planet today. It's enough to go around the equator 35 times. So, I'm sure that most of you can easily recognize the importance of the network of undersea fiber optic cables.

The big question that many of you might have is, how exactly do you do this? How do you build over a million kilometers of fiber optic cables strong enough to survive on the bottom of the ocean and lay it down with enough precision and care not to damage it? Well, let's start with how undersea cables are made.

At the core of these cables are the optical fibers themselves, which are thin strands of ultra-pure glass capable of guiding light signals over thousands of kilometers. These fibers are typically grouped into bundles and coated with a protected gel or buffer material to shield them from moisture and physical stress. Surrounding the fibers is a metallic tube, often made of copper or aluminum, which serves two key functions. It protects the fibers mechanically, but also conducts electrical power.

The electrical power is necessary to operate repeaters, which are specialized devices placed at regular intervals of about 50 to 100 kilometers or 30 to 60 miles that amplify the optical signals to prevent degradation of the signal over long distances. Outside of the metallic tube lies a layer of polycarbonate or polyethylene insulation that provides water resistance and additional durability.

For shallow water deployments where the risk of damage from ship anchors or fishing equipment is higher, the cable is reinforced with one or more layers of steel wire armoring. These wires are helically wound around the insulated core, making the cable significantly more robust and heavier. In deeper waters where external threats are minimal, cables are lighter and lack armoring to reduce deployment complexity and costs.

The entire structure is then covered with an outer, waterproof sheath, typically made from polyethylene, to seal and protect the internal components from corrosion and the immense pressure of the deep sea. Depending on where the cable will be laid, shallow continental shelves, rugged seamounts, or deep ocean plains, the specific layering and construction may vary, but the goal is always the same: to ensure that the optical signal can travel securely and reliably across the ocean for decades.

Once a cable is manufactured, often in continuous segments several thousand kilometers long, it's carefully coiled into large circular tanks at the manufacturing facility. These tanks, sometimes 30 meters or 100 feet in diameter and several meters deep, preserve the gentle curvature of the cable to avoid kinks or stress that might damage the delicate optical fibers inside.

When it's time to load the cable onto a ship, the coils are slowly transferred from the storage tanks into similar circular tanks on board the cable-laying vessel. This transfer process can take several days or even weeks depending on the length of the cable and the proximity of the manufacturing site to the port. The ship's tanks are designed to store cable in a spiral pattern, ensuring that it can be played out smoothly during deployment.

Sophisticated tension control systems are used throughout the loading process to maintain consistent pressure and prevent overbending or crushing of the cable. Once the ship is fully loaded and at sea, it follows a carefully pre-surveyed route guided by GPS and detailed oceanographic data. As the vessel moves along the planned path, the cable is slowly fed out from the storage tanks using a system of rollers, drums, and tensioners that ensures the cable unspools at a controlled rate.

In deep ocean waters, the cable is simply released and allowed to settle gently onto the seafloor under its own weight. However, in shallow coastal areas where the risk of damage from fishing, anchoring, or currents is higher, the cable is often buried beneath the seabed using a remotely operated plow that creates a narrow trench and lays the cable into it before covering it back up.

Throughout the process, the onboard technicians monitor cable tension, seabed topography, and the ship's position in real time to ensure proper placement and to avoid entanglement or contact with undersea hazards. Repeaters, if necessary, are spliced into the cable during the manufacturing phase or onboard the ship and are deployed seamlessly as part of the cable train. The entire operation can take several weeks to several months depending on the length of the cable, the weather, and the complexity of the seabed terrain.

Once complete, the cable is connected to landing stations at both ends where it interfaces with terrestrial networks and begins transmitting data across the ocean. The strategic importance of global connectivity shapes the economics of laying undersea fiber optic cables. Laying a cable involves a massive upfront investment with the hope of meeting long-term data demand.

These cables cost tens to hundreds of millions of dollars per system, with total project costs varying depending on the length, capacity, route, complexity, and other geopolitical factors. On average, the cost per kilometer ranges from $25,000 to $50,000, which includes cable manufacturing, marine surveys, cable laying using specialized ships, installation of landing stations, and compliance with legal and regulatory requirements.

Historically, undersea cables were built by consortia of telecom companies such as AT&T, British Telecom, Orange, or Nippon Telegraph and Telephone, who pooled resources to build infrastructure that no one could afford alone. These joint ventures would share bandwidth and maintenance responsibilities.

In recent years, however, big tech companies have taken the lead. Google, Facebook, Amazon, and Microsoft now fund or co-own many major new cables. These companies need vast amounts of low-latency, high-capacity bandwidth to support their global data centers and cloud platforms. When a cable is laid, much of it might not be used immediately. This is called dark fiber. It might be turned on at a later date to meet increased demand.

You might be wondering, given that there are tens to hundreds of millions of dollars invested in a thin cable at the bottom of the ocean, what happens if the cable breaks? When an undersea fiber optic cable breaks, the disruption is almost immediately detected by network monitoring systems. These systems notice a sudden loss of signal or significant increase in transmission errors, prompting engineers to begin diagnostic procedures.

To determine the exact location of the fault, they use a technique called optical time domain reflectometry, which sends pulses of light through the cable and measures the reflections that bounce back from the break. This allows them to estimate the fault's location with surprising accuracy, often within a few hundred meters. Once the break is located, a cable repair ship is then dispatched to the site.

These ships are equipped with specialized equipment and carry trained crews capable of retrieving, repairing, and redeploying undersea cables. The ship sails to the approximate location of the fault using GPS data and cable route maps to pinpoint the location. If the cable is in shallow waters, a grapnel, a kind of underwater hook, is dragged along the seabed to snag it and lift the cable. In deeper water, remotely operated vehicles or specially weighted grapnels are used to retrieve the cable.

Depending on the depth and the condition of the cable, the crew may have to cut the cable on the seafloor and retrieve both ends separately. Once the damaged section is brought aboard the ship, technicians cut out the damaged portion and splice in a new segment of cable. The optical fibers are fused with high precision to preserve signal quality, and the entire repair is sealed within a waterproof, pressure-resistant casing. The spliced cable is tested on board to ensure signal integrity, and then it's carefully lowered back to the seafloor.

In areas where the cable is at risk of future damage, such as along a busy shipping lane or fishing area, it might be buried again using a sea plow. The entire process from detection to full repair can take anywhere from several days to a few weeks depending on the cable's location, the severity of the damage, weather conditions, and ship availability. More undersea optical fibers will be created and laid in the future. Some of this will be the replacement of older fiber with more advanced higher capacity fiber.

But some of this will involve new connections to meet the almost insatiable demand for bandwidth worldwide. And this is because our modern world and its communications are all built on a network that exists at the bottom of the sea. The executive producer of Everything Everywhere Daily is Charles Daniel. The associate producers are Austin Oakton and Cameron Kiefer. I want to thank everyone who supports the show over on Patreon. Your support helps make this podcast possible.

I'd also like to thank all the members of the Everything Everywhere community who are active on the Facebook group and the Discord server. If you'd like to join in the discussion, there are links to both in the show notes. And as always, if you leave a review or send me a boostagram, you too can have it read on the show.